-

English

-

Français

-

italiano

-

日本語

-

Nederlands

-

ไทย

-

Polski

-

አማርኛ

-

ພາສາລາວ

-

ភាសាខ្មែរ

-

Bahasa Melayu

-

தமிழ்

-

Bahasa Indonesia

-

فارسی

More Language

Views: 0 Author: Site Editor Publish Time: 2025-04-04 Origin: Site

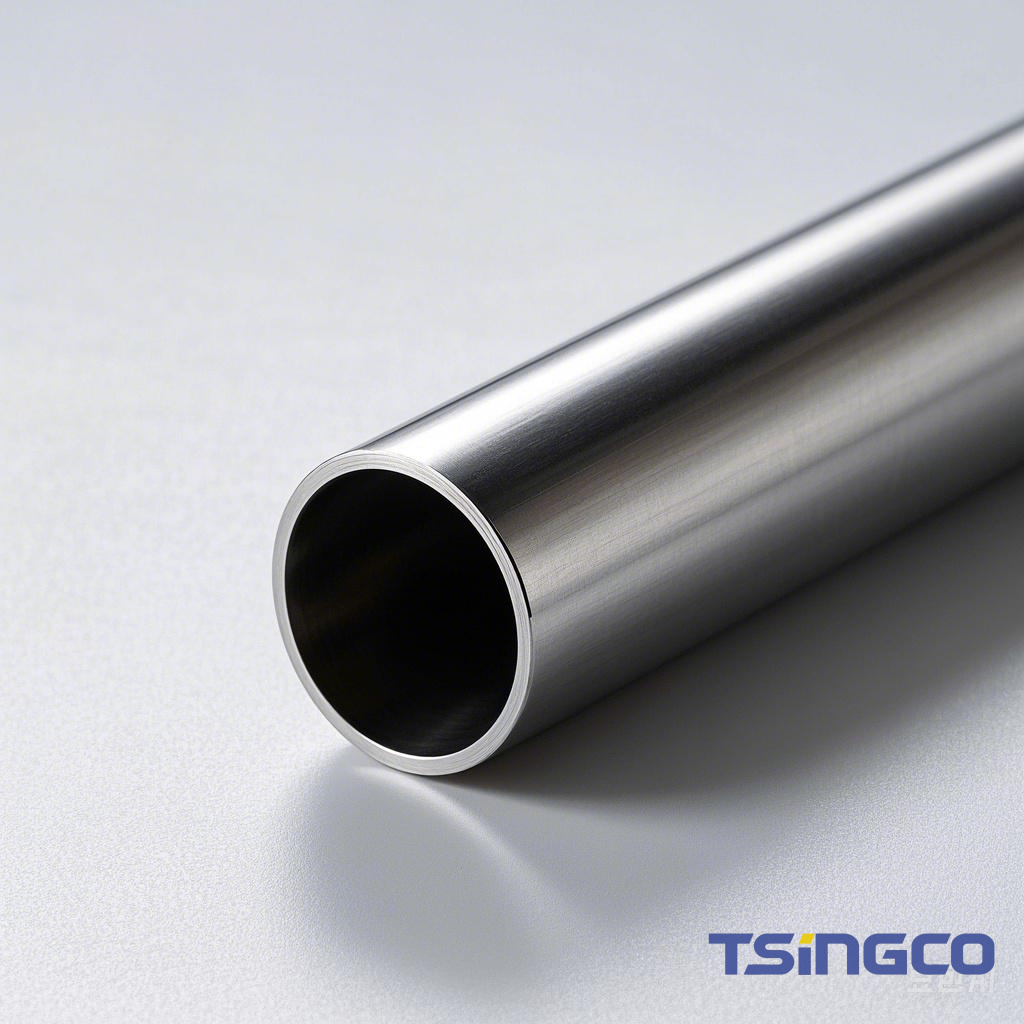

Aerospace engineering demands materials that are strong, reliable, and able to perform in extreme conditions. Among the materials that meet these rigorous requirements are nickel alloy tubes. These tubes play an essential role in various aerospace applications, from jet engines to structural components. But what makes nickel alloys so special, and why are they so widely used in the aerospace industry?

In this article, we’ll explore the unique properties of nickel alloy tubes, their applications in aerospace, and why they are a top choice for aerospace manufacturers. Additionally, we will discuss how TSINGCO's nickel alloy tubes provide a reliable solution for your aerospace projects.

Nickel alloys are well known for their ability to withstand high temperatures and extreme pressures. In aerospace, where components are exposed to both conditions, these materials are critical for ensuring performance and longevity. Nickel alloy tubes maintain their strength and integrity even at temperatures exceeding 1000°C, which makes them perfect for applications in engines and exhaust systems.

The high melting point and resistance to thermal degradation allow these tubes to function effectively in the most demanding aerospace environments, such as the high-pressure areas of jet engines.

Aerospace components must endure exposure to a wide range of environmental factors, including moisture, chemicals, and high-altitude atmospheric conditions. Nickel alloy tubes, such as Inconel and Hastelloy, offer superior resistance to corrosion, ensuring that parts remain functional and reliable throughout their lifespan. This corrosion resistance is crucial in preventing failures and enhancing the safety and performance of aerospace systems.

Aerospace applications demand materials that can handle high-stress conditions without failing. Nickel alloy tubes exhibit remarkable durability and strength, making them ideal for structural components, fuel systems, and hydraulic lines. These materials perform well even under mechanical stress, vibration, and repeated thermal cycling, which are common in aerospace environments.

Jet engines operate under some of the most extreme conditions in aerospace, with turbine blades, exhaust nozzles, and combustion chambers exposed to high temperatures and mechanical stresses. Nickel alloy tubes are used in these critical components due to their ability to maintain structural integrity at elevated temperatures. They ensure the efficiency and safety of jet engines by preventing failure and ensuring optimal performance.

In particular, alloys like Inconel are used extensively in turbine blades and other engine parts because of their superior resistance to heat and oxidation. By incorporating nickel alloy tubes into these systems, aerospace engineers can achieve higher performance and longer service life for their engines.

Fuel systems in aircraft need to be both lightweight and durable. Nickel alloy tubes are used to transport fuel in these systems because they offer the perfect balance of strength, weight, and corrosion resistance. They are resistant to the harmful effects of fuel and other chemicals commonly found in aviation fuel systems, ensuring that the components remain leak-free and perform consistently over time.

These tubes also perform well under the temperature fluctuations experienced at high altitudes, where freezing conditions and high-pressure environments can create significant challenges for materials used in fuel systems.

Hydraulic and pneumatic systems are essential for controlling flight surfaces, braking systems, and other critical operations in aircraft. Nickel alloy tubes are widely used in these systems due to their ability to resist corrosion and maintain structural integrity under high pressure. Whether for actuators, valves, or lines within hydraulic systems, these tubes ensure reliable, long-term operation even in harsh aerospace conditions.

Their strength and resistance to wear make them a preferred choice for fluid power systems that demand efficiency and dependability.

Nickel alloys are also used in various structural components of aircraft, such as exhaust systems, landing gears, and heat exchangers. These parts need to be lightweight while also being able to withstand thermal and mechanical stresses. Nickel alloy tubes are often chosen for these applications due to their strength-to-weight ratio and resistance to high temperatures. By using these materials, manufacturers can build more efficient, durable aircraft that offer enhanced fuel efficiency and longer lifespans.

Nickel alloy tubes contribute to the overall performance of aerospace systems. Their ability to withstand high temperatures and mechanical stress allows for more efficient engines, fuel systems, and structural components. These materials enable aerospace systems to run at higher temperatures, which increases the overall efficiency of the system while reducing energy consumption and emissions.

The durability and corrosion resistance of nickel alloy tubes significantly reduce the frequency of maintenance and replacement in aerospace applications. These materials can handle the extreme conditions typical of aerospace systems, such as high altitudes and fluctuating temperatures, without degrading. This translates to lower maintenance costs, fewer downtime, and longer operational lifespans for critical components.

In aerospace, safety is paramount. Nickel alloy tubes provide the reliability needed to ensure that components function optimally in extreme environments. By offering excellent resistance to oxidation, corrosion, and thermal fatigue, these tubes help prevent material failure, ensuring the safety of both aircraft and passengers.

While providing excellent strength and durability, nickel alloy tubes are also relatively lightweight. This characteristic is crucial for aerospace components, where reducing weight can lead to improved fuel efficiency and overall performance. The use of lightweight nickel alloy tubes allows for the construction of stronger, more efficient systems without compromising on weight.

At TSINGCO, we offer high-quality nickel alloy tubes that meet the stringent requirements of the aerospace industry. Our products are designed for maximum durability, strength, and resistance to corrosion and heat. Whether you’re looking for tubes for jet engines, fuel systems, or hydraulic lines, our nickel alloys provide the perfect solution for your aerospace projects.

By choosing TSINGCO, you ensure that your aerospace components are built with the highest quality materials, helping you achieve optimal performance, safety, and longevity.

Nickel alloy tubes play an indispensable role in aerospace engineering, providing the strength, durability, and corrosion resistance necessary for high-performance applications. From jet engines to fuel systems and structural components, these tubes ensure the efficiency and reliability of aerospace systems. By choosing high-quality materials like those offered by TSINGCO, you can enhance the performance and longevity of your aerospace components.

A: Nickel alloy tubes are used in jet engines because of their high-temperature resistance, strength, and corrosion resistance, ensuring optimal performance in extreme conditions.

A: Yes, nickel alloy tubes are designed to perform well under high-pressure conditions, making them ideal for aerospace hydraulic and fuel systems.

A: Nickel alloy tubes are lightweight, corrosion-resistant, and capable of performing under fluctuating temperatures, making them perfect for aircraft fuel systems.

A: Nickel alloy tubes ensure the safety of aircraft systems by offering superior resistance to wear, corrosion, and thermal stress, reducing the risk of failure.