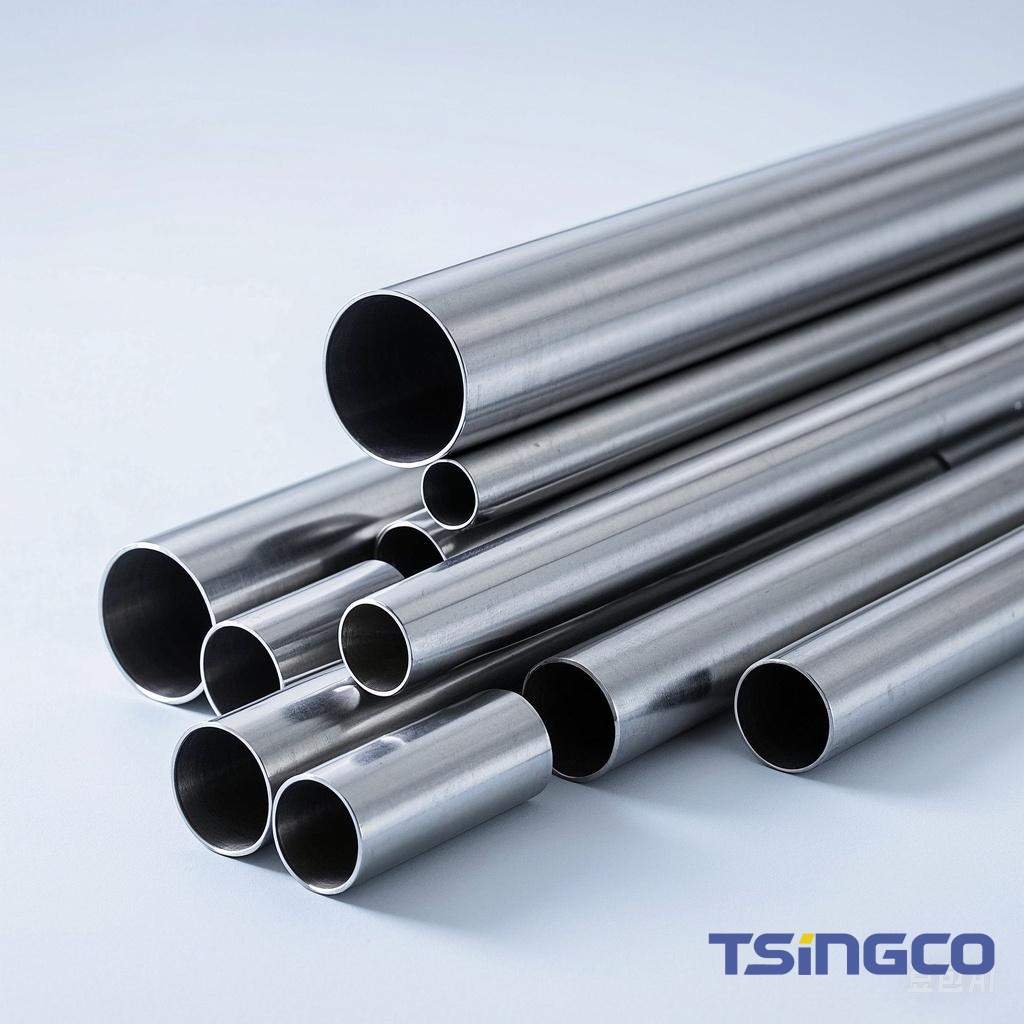

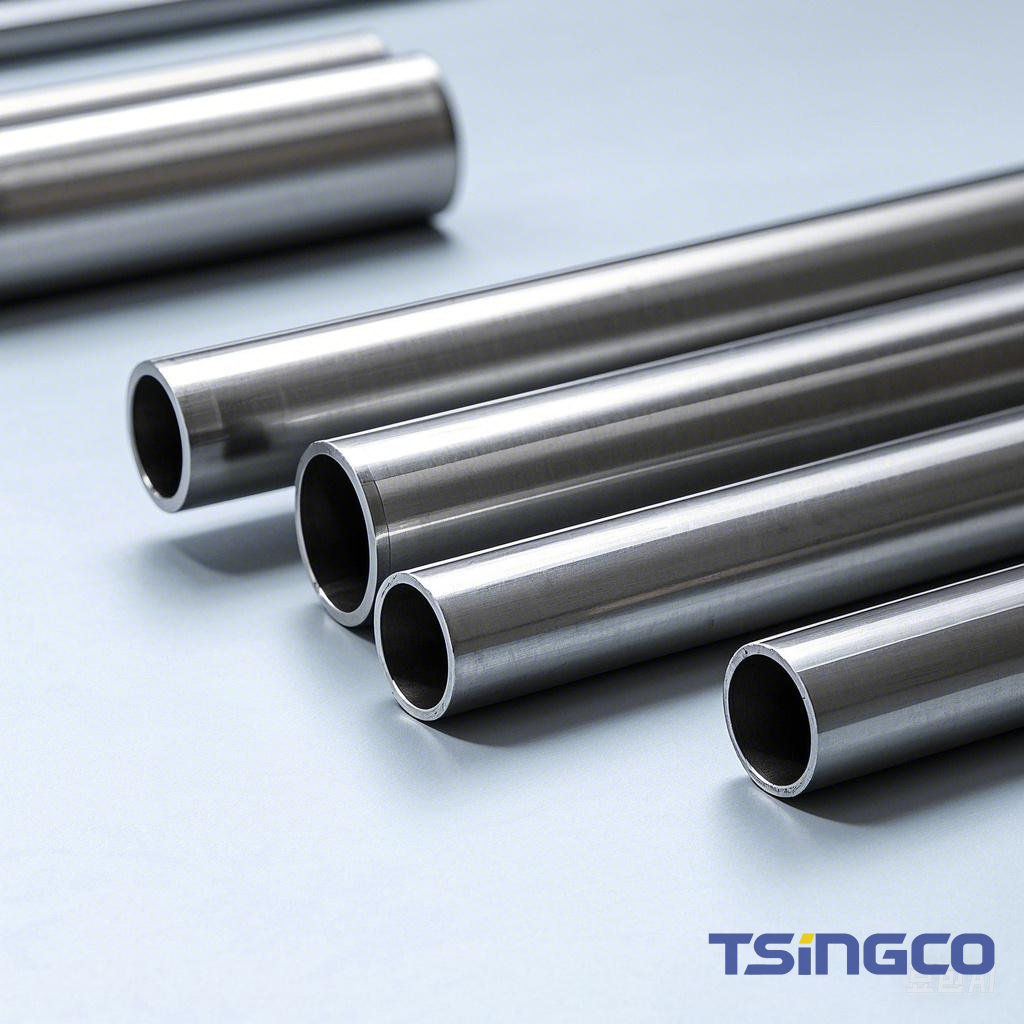

Premium Bright Annealed Tubes for High-Quality Performance

Get to know the brilliance of our top-notch Bright Annealed Tube. We are one of the major suppliers for high-quality Bright Annealed Tubes, and we pledge outstanding product standards that cater to even your most stringent demands.

Our Bright Annealed Tube Collection

Introducing our high-quality stainless steel Bright Annealed Tube Collection. It boasts high tensile strength and corrosion resistance, meeting ASTM and JIS standards.

Philippine Warehouse Ready Stock! ASTM A554 Decorative Pipes - Same Day Delivery to QC City

Model NO.:Pipe

Material:Stainless Steel

Surface Treatment:Varnishing/Polished/Oiled/Antispetical

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry,Chemical Industry, Mining

Section Shape:Round

End:PE/Be

Delivery Time:15-50days

Certs:ISO 9001-2008, CE. PED, Ts

Tolerance:+-0.05mm

Standard:AISI, ASTM, DIN, JIS, GB

Material Grade:304 304/304L 304h 30432(Super 304h)321 321H 316 31

Specification:as demand

Trademark:SINCO

Industrial-Grade AISI304 ASTM A270 DN200 1.4948 Aus Electro Polished Stainless Steel Pipe for Petrochemical

Model NO.:Pipe

Material:Stainless Steel

Surface Treatment:Varnishing/Polished/Oiled/Antispetical

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry,Chemical Industry, Mining

Section Shape:Round

End:PE/Be

Delivery Time:15-50days

Tolerance:+-0.05mm

Standard:AISI, ASTM, DIN, JIS, GB

Material Grade:304 304/304L 304h 30432(Super 304h)321 321H 316 31

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

Specification:as demand

Trademark:SINCO

Professional Sanitary Grade S2205 S31803 316L 304 Super Duplex Stainless Steel Circle Product Pipe Seamless Bright Mirror Tube Price Wholesale Market

Model NO.:tube

Material:Stainless Steel

Surface Treatment:Annealing and Pickling/Polished;

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose

Section Shape:Round

Wall Thickness:0.5-30mm

End:PE/Be

Length:5m-12m or Depend on Your Request

Certificate:ABS, BV, Dnv, CCS, TUV etc

Custom:Available

Company:Supplier in Wenzhou

Material Grade:304h 316 316L 316h 321 321H 317L 347 347H 310S;

Transport Package:Nylon Bags or Wooden Box

Specification:6-630MM

Spotless Ep F317L DN125 Stainless Exhaust Mirror Polishing Pipe with Milk Surface for Metallurgy

Model NO.:Pipe

Material:Stainless Steel

Surface Treatment:Varnishing/Polished/Oiled/Antispetical

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry,Chemical Industry, Mining

Section Shape:Round

End:PE/Be

Delivery Time:15-50days

Certs:ISO 9001-2008, CE. PED, Ts

Tolerance:+-0.05mm

Standard:AISI, ASTM, DIN, JIS, GB

Material Grade:304 304/304L 304h 30432(Super 304h)321 321H 316 31

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

Specification:as demand

Trademark:SINCO

316L 317L 347H Mirror 9.53mm Hot Rolled Seamless Stainless Steel Ba Tube Support

Model NO.:316L pipe

Material:Stainless Steel /Alloy Steel

Surface Treatment:Varnishing/Polished/Antispetical/Oiled

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry,Chemical Industry, Mining, Construction & Decoration, Special Purpose

Section Shape:Round

End:PE/Be

Wall Thickness:0.5mm-60mm

Length:5m-12m

Delivery Time:15-50days

Certs:ISO 9001-2008, CE. PED, Ts

Material Grade:304 316 304L 3126L 904L 2507 2205 317L 347H

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

SNI Certified 304 Stainless Tube - Thailand Food Processing Equipment Piping

Model NO.:Pipe

Material:304 316 321 Duplex Stainless etc

Surface Treatment:Varinished, Polished, Antiseptical, Oiled

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Chemical Industry,Mining

Section Shape:Round

Standard:ASTM, AISI, GB, JIS, DIN, En

Grade:300 Series

Shape:Round

Quality:Good

Company:Manufacturer in Wenzhou

Customize:Available

Techinics:Welded

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

Specification:as demand

Trademark:SINCO

Origin:China

Australia-Sea Cross-Border Supply-AS/NZS 1528 Stainless Tube (Polished/Rough Surface)

Model NO.:stainless steel pipe/tube

Material:Stainless Steel

Surface Treatment:Vanishing/Polished /Oiled /Antispetical

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry,Chemical Industry, Mining, Construction & Decoration, Special Purpose

Section Shape:Round

End:PE/Be

Certificate:ISO, CE, BV, Ts, PE

Custom:Available

Yield:300, 000 Tons Per Year

Sandard:AISI, ASTM, DIN, JIS, GB, ASME, En, GOST

Steel Grade:300 Series;

Material Grade:304 316 316L 310S 321 317 317L 317ln

Transport Package:Nylon Bags and Wooden Box

Specification:as demand

Trademark:SINCO

Origin:China

Ss Round Stainless Steel Tubes for Manila Furniture Exporters - Cheaper Than Korean Suppliers

Model NO.:Pipe

Material:Stainless Steel

Surface Treatment:Varnishing/Polished/Oiled/Antispetical

Usage:Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry,Chemical Industry, Mining

Section Shape:Round

End:PE/Be

Delivery Time:15-50days

Certs:ISO 9001-2008, CE. PED, Ts

Tolerance:+-0.05mm

Standard:AISI, ASTM, DIN, JIS, GB

Material Grade:304 304/304L 304h 30432(Super 304h)321 321H 316 31

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

Specification:as demand

Trademark:SINCO

ASTM A270 Tp321 Pipe Sch5s 10s Seamless Stainless Steel Bright Annealing High Purity-Grade Clean Tube Made in China for Milk Filler

Length:5m-12m or Depend on Your Request

Certificate:ISO, CE, BV, Ts, PE

Custom:Available

Company:Supplier in Wenzhou

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

Specification:as demand

Trademark:SINCO

Material:Stainless Steel

Surface Treatment:Varnishing/Polished/Antiseptical/Oiled

Usage:Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special purpose

Wall Thickness:0.065"-0.12"

End:PE/Be

Length:5m-12m or Depend on Your Request

Certificate:ISO, CE, BV, Ts, PE

Custom:Available

Company:Supplier in Wenzhou

Transport Package:Nuded Cargo or Nylon Bags or Wooden Box

Specification:as demand

Trademark:SINCO

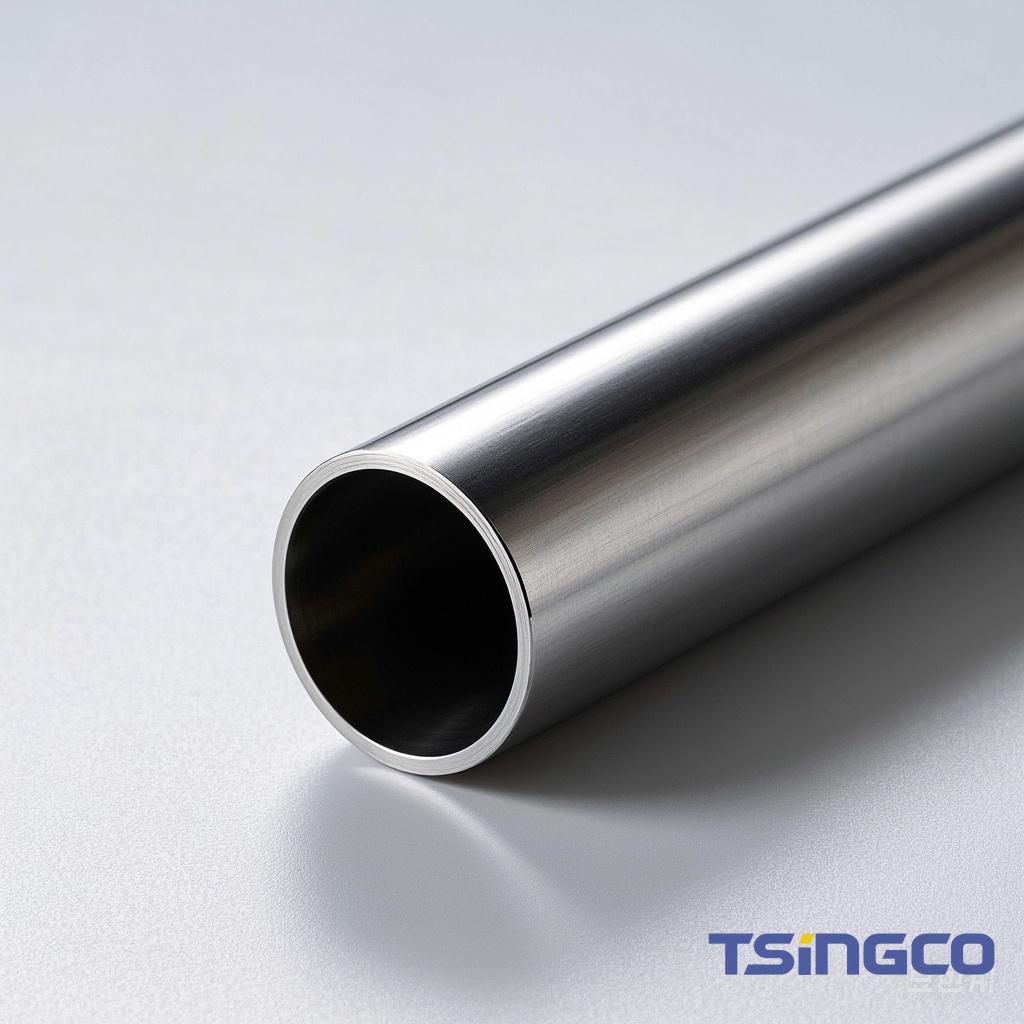

Detailed Specifications of Bright Annealed Tubes

Dive into TSINGCO’s bright annealed tubes that boast exquisite qualities. They are soft yet fine, corrosion-resistant and heat-resistant, durable with good tensile properties and waterproof; they even offer exceptional electromagnetic shielding. These tubes find their ideal use in automation instruments and wire protection high voltage cables, along with applications in the chemical, petroleum, and medical sectors.

Specifications

Parameter | Value |

|---|---|

Outer Diameter | Φ0.4-Φ16.0mm |

Wall Thickness | 0.1-2.0mm |

Length | Up to 18000mm |

Standards | ASTM A269, A270, A312, A554, A249, DIN 17457, JIS G3459, GB/T12770-2002, GB/T12771-2008 |

Tolerances

Type | Diameter Tolerance (mm) | Wall Thickness Tolerance (mm) |

|---|---|---|

Tubes | ±0.30 | +0.05 -0.00 |

Pipes Schedule 5S | +0.1 -0.00 | +0.1 -0.00 |

Pipes Schedule 10S | +0.01 -0.15 | ±0.1 |

Delivery State

Delivery State Code | Type |

|---|---|

HFD | Hot finished heat treated, descaled |

CFD | Cold finished heat treated, descaled |

CFA | Cold finished bright annealed |

CFG | Cold finished heat treated, ground |

CFP | Cold finished heat treated, polished |

Note: Customized sizes and additional requirements are available upon request. For more information or to place an order, please contact our sales team.

The Making of Bright Annealed Tubes

Dive into the detailed manufacturing process of Bright Annealed Tubes, highlighting essential production steps from raw material preparation to the final polished product. Discover how TSINGCO implements advanced techniques and equipment to ensure top-notch quality, reflecting our commitment to excellence.

Raw Material Polishing for Stainless Steel Tubes

In the production of Bright Annealed Tubes, stainless steel raw materials are not directly used but instead polished carefully to eliminate any impurity and ensure the surface is clean. This step is critical in achieving a flawless finish which is typical for high quality tubes. We use modern equipment at TSINGCO's to polish materials that help us enhance both durability and outlook; quality isn't something we compromise.

Advanced Cold Rolling Techniques in Tube Manufacturing

Bright Annealed Tubes are produced where cold rolling holds a vital position. It is instrumental in helping attain the accurate dimensions and surface finish that is smooth for these tubes. With the latest cold rolling machinery, TSINGCO guarantees top-notch precision and quality on every tube, which finds use in a wide array of industrial applications due to their suitability.

High-Temperature Bright Annealing Furnace Processes

The bright annealing process involves heating the tubes in a specialized furnace to achieve a bright, reflective surface. This step eliminates any internal stresses and enhances corrosion resistance. TSINGCO’s high-temperature bright annealing furnace ensures a uniform finish, crucial for maintaining the structural integrity of the tubes.

Precision Straightening of Stainless Steel Tubes

To guarantee that tubes are straightened perfectly, after the annealing process, TSINGCO must utilize advanced machines that can rectify any distortions and make sure the tubes are straight. The accurate alignment of tubes through this meticulous straightening process is very important especially to those applications where high precision and dependability are key considerations.

Comprehensive Degreasing and Cleaning Procedures

Degreasing is a critical step. It's the one that must be taken to eliminate any oils and other contaminants present on the tube surfaces. At TSINGCO, we employ advanced degreasing solutions and methods that can completely rid the tubes of such unwanted elements. This makes them fit for further processes or even immediate use in clean environments like those in sanitary or medical applications.

Thorough Inspection and Quality Assurance

Quality assurance is key in the manufacturing of Bright Annealed Tubes. In this regard, TSINGCO has adopted stringent inspection methods that cover size, surface and analytical verifications to affirm conformance of every tube to the set standards. Our dedication to quality management assures provision of dependable products that not only meet but also address your specific requirements, ultimately adding worth to your undertakings.

Our Comprehensive Support Services

The post-sales support service module is designed to cater for your needs in a comprehensive manner, which assures you total satisfaction and peace of mind. This is achieved through our world-class customer care services, strong warranties and technical assistance from the experts. We take pride in our state-of-the-art equipment and outstanding workforce who are dedicated to paying attention to even the smallest details with an upbeat attitude towards work and a time-effective information delivery system that ensures all customer needs are well taken care of.

Exceptional Customer Service

The customer service we offer is one of a kind. We respond quickly to inquiries and resolve issues with specialized information, offering expert knowledge. Our committed group of support staff is easily reachable for your help at any point, and this makes sure that every contact you make with us leaves you satisfied.

Comprehensive Warranty Protection

We have comprehensive protection in our warranty services for your investments. We provide a wide range of coverage on many of our products, including maintenance and replacement, so that you can have peace of mind knowing that we have you covered.

Reliable Technical Support

We have a highly skilled technical support group who can deal with any issue. We give expert advice and suggestions for how to maintain our products and make them perform at their best; this makes sure that every task is carried out smoothly and efficiently.

Detailed Product Documentation

We have produced exhaustive product documentation with installation instructions, maintenance procedures and specification notes; all are meant to provide you with ample guidance on how to use and take care of our products appropriately.

Swift Problem Resolution

We make it a point to address any issues you come across quickly and without delay. Our staff is well-trained in identifying and resolving issues swiftly, which helps in reducing downtimes so that your systems can continue functioning properly without any interruptions.

Proactive Maintenance Plans

Proactive maintenance plans are what we offer and they suit your unique needs. These preventive plans help in stopping potential issues: this is done through periodical check-ups and servicing that ensures the durability and functionality of your equipment is maintained all along.

Custom Support Solutions

It is acknowledged that individual customers might have distinctive needs. Therefore, we offer personalized support services designed to meet your operational requirements distinctly with the objective of achieving efficiency and contentment.

User Training Programs

The design of our user training programs ensures that your team is well prepared to efficiently use and keep up our products. We provide training courses at different levels and ensure everyone is proficient in handling the equipment through comprehensive sessions.

Why Choose TSINGCO Bright Annealed Tubes?

Uncover what makes TSINGCO® Bright Annealed Tubes exceptional among other options available in the market. Our module compares and brings to light the superiority of TSINGCO tubes, making it clear that quality, precision and manufacturing mastery is where our forte lies.

Surface Finish Quality of TSINGCO Bright Annealed Tubes vs Competitors

TSINGCO® Bright Annealed Tubes produce a surface finish quality that can't be matched, obtaining an immaculate sheen without any imperfections present. On the flip side, competitors tend to send out tubes riddled with impurities and inconsistencies on their surface. Our precision-engineered tubes go through rigorous polishing procedures which results in a finish so reflective it acts as a mirror; this dual functionality significantly augments both visual appeal and practical performance qualities of the tube. Some competing products might need further processing just to get close to what we offer with our finish level— bringing added costs and time wastage into your projects. Opting for TSINGCO means you're getting top-notch surface integrity: say goodbye to contamination risks and hello (or rather a lengthier hello) to product lifespan enhancements including better applicability for instrumentations or bio-pharmaceutical systems!

Dimensional Accuracy: TSINGCO vs Industry Standards

TSINGCO® Bright Annealed Tubes— they're good. They're really good at keeping specific dimensions. Like really, really good. The folks at TSINGCO use some pretty advanced manufacturing methods to make sure every tube is up to par with (or even above) standards like GB, ASTM, and JIS because we need global standards for this global world. Other companies might not be able to keep up with these tight tolerances— which can pose problems later when you're trying to fit a TSINGCO tube into a high-tech system. But if you go with TSINGCO, you're looking at minimal differences in tube dimensions: important for fields where precision is key (think aerospace or medical). Choose TSINGCO and choose consistency.

Corrosion Resistance: TSINGCO Bright Annealed Tubes vs Other Brands

The TSINGCO® Bright Annealed Tubes show an impressive anti-corrosion ability because the stainless steel used is of a high quality and the annealing processes are precisely done. Our tubes excel in tough conditions; they do not oxidize or degrade easily which makes them stay effective for long periods. Competitor tubes might develop corrosion sooner— notably when exposed to hostile media or high temperatures, hence using TSINGCO is cost-effective and critical for sectors like chemicals and marine where operational continuity and durability are important. Maintenance costs are reduced by the use of TSINGCO: any product that fails would have more negative impacts on end users than benefits from its availability.

Cleanliness and Purity: TSINGCO vs Competing Bright Annealed Tubes

Cleanliness and purity are essential, especially in the pharmaceuticals and food processing industries. TSINGCO® Bright Annealed Tubes go through very intense cleaning procedures, which assure that the levels of purity are ultra-high and with very minimal contamination risks. Other competitors may not take such measures, thus they risk cross-contamination which could compromise their product quality. Moreover, the fine interior surface finish of TSINGCO tubes allows easy sanitation and sterilization processes— factors critical for upholding high hygiene standards. This has made TSINGCO be preferred among other choices, particularly for applications where high levels of cleanliness and purity are required.

What Our Clients Say

Michael Lin

TSINGCO’s bright annealed tubes are top-notch. The quality and finish exceeded my expectations. Highly recommended!

Sarah Tan

I am extremely satisfied with the product quality and customer service provided by TSINGCO. They went above and beyond to meet my requirements.

James Wong

The durability and precision of TSINGCO’s bright annealed tubes have significantly improved our production processes. A great investment!

Emily Zhang

TSINGCO offers exceptional products and unparalleled customer support. The bright annealed tubes we purchased were perfect.

David Chen

I have been using TSINGCO's bright annealed tubes for years, and they never disappoint. Consistent quality and reliable service.

Linda Wang

From the first inquiry to the final delivery, TSINGCO provided an outstanding experience. Highly dependable and professional.

Bright Annealed Tubes in Action

The Bright Annealed Tubes have been key contributors to phenomenal results across a variety of applications. In these case studies, we feature the unique characteristics, effectiveness, and outcomes of using these stainless steel tubes in different projects that we highlight.

Bright Annealed Tubes in Pharmaceutical Industry

The incorporation of our Bright Annealed Tubes into the production lines of a major pharmaceutical manufacturing facility took place. This was due to the high corrosion resistance of the tubes which were used to transport various chemicals because it is an essential aspect in such operations. Moreover, smooth internal surfaces reduce contamination that could be caused significantly: as a result, product purity remained uncompromised while also cutting down maintenance costs and ensuring durability contributed further benefits towards operational efficiency that increased by 25%, coupled with downtime reduction. In addition, uniformity and excellence in tabulation along tube walls meant that the production processes were even more streamlined— this fit perfectly with those strict industry standards that are governing such sectors.

Enhancing Efficiency in Chemical Plants with Bright Annealed Tubes

A major chemical plant adopted the use of our Bright Annealed Tubes in their heat exchangers plus control lines. The capacity of these tubes to withstand high temperatures of steam and ammonia corrosion was critical for the plant’s operational efficiency while still maintaining system integrity under extreme conditions. As a result, the implementation saw a decrease of up to 30% in coolant system failures and maintenance overheads— in addition, the thermal conductivity from these tubes also resulted into more effective exchange which meant savings on energy with better performance on top. These distinctive qualities not only helped the plant meet its safety and reliability standards but go above them; it made them stand out as an industry leader in operational efficiency.

Bright Annealed Tubes in Aerospace Communication Systems

The Bright Annealed Tubes took a pivotal role in the upgrade of communication systems at a high-tech aerospace communications facility where they are used. The selection of the tubes was based on their surface that has no oxide or any other coating, inside and outside, ensuring perfect precision without compromise to reliability which is vital in space systems. The response was noted by the facility with better clarity of signals and durability of equipment— achieved through uniform walls on all tubes and their thermal performance due to good heat exchange properties. Moreover, even after lightening weight without losing strength (quality), another important advantage was still found: ease in achieving efficiency and effectiveness, as it helped play a role towards production components for space systems.

Revolutionizing Heat Exchangers in Power Plants with Bright Annealed Tubes

We have been in the high-temperature Bright Annealed Tubes sector since 2015. Our tubes played a very important role in changing the heat exchangers of a major power plant. The plant was to use these tubes because they have good thermal conductivity and do not form scaling or oxide: as a result, their heat exchange efficiency was improved by 35%. Not only did this change enhance how the plant managed its thermal operation but it also substantially reduced the number of maintenance exercises together with their costs. The long service life coupled with reliability demonstrated by these tubes clearly showed that they were worth an investment; these contributed to sustainable production and supply of uninterrupted power.

Transforming Beverage Production Facilities with Bright Annealed Tubes

A beverage production facility sought after our Bright Annealed Tubes, aiming to innovate the manufacturing line and remove contaminant risk issues. This paring delivered in turn an enhanced elimination of maintenance downtime: in the path of the flowing liquid, the surface of these tubes provided an effective barrier to corrosion. The longevity was also ensured due to anti-corrosive properties of the tubes' material while, having smooth internal surfaces, these components do not need a complicated cleaning process that is difficult to reach. It's easy enough. Plus sterilization procedures can be performed easily. In conclusion: a 20% increase in production capacity was observed alongside consistent product quality due to reliable performance and reduced maintenance demands by stainless steel tubes with smooth internal surfaces.

Marine Applications: Bright Annealed Tubes in Shipbuilding

The use of Bright Annealed Tubes in a structural sense, these can be stated as a part of cutting-edge shipbuilding projects which are able to fit into all components and pipes where steel tubes are applicable and have features for the resistance of sea water environment greatly. The particular contribution of these tubes was to improve the durability, operation efficiency with thermal conductivity providing heat management (which is optimal) due to no presence of any welds that could create leak points plus the seamless walls that guarantee structural integrity. This contributed significantly towards reducing maintenance costs; enhancing safety, reliability; and curbing production lead time at the shipyard by 15% as reported by demanding marine applications effective.

Bright Annealed Tubes - Your Questions Answered

Bright Annealed Tubes are stainless steel tubes that undergo an annealing process in a controlled atmosphere furnace. This results in a shiny, smooth surface finish, enhancing corrosion resistance and appearance. These tubes are ideal for industries requiring high precision and quality, such as pharmaceuticals and food processing.

The benefits of Bright Annealed Tubes include superior corrosion resistance, a smooth surface finish, and enhanced mechanical properties. The annealed process eliminates scale formation ensuring better weldability. Applications include medical devices, instrumentation, and chemical processing.

Yes, TSINGCO offers customization for Bright Annealed Tubes. You can specify the length, diameter, and wall thickness according to your needs, ensuring a perfect fit for your application. Our facilities are equipped to handle bespoke requirements efficiently.

TSINGCO's Bright Annealed Tubes are made from high-quality stainless steel, including grades such as 304, 316, and 321. These materials provide excellent durability, resistance to corrosion, and heat resistance, suitable for various industrial applications.

Quality assurance is integral to TSINGCO’s operations. Each Bright Annealed Tube undergoes rigorous testing including dimensional inspections, surface finish checks, and corrosion resistance tests. Our adherence to international standards like ASTM ensures top-tier product quality.

Get in Touch with Us Today

Looking for high-quality bright annealed tubes? Contact TSINGCO® today for inquiries or competitive quotes on our stainless steel pipes, fittings, and flange series products. Our team is ready to assist you with any questions or requests. Trust TSINGCO® – where precision meets excellence.