Discover Advanced Stainless Steel Pipes for Petrochemical Industry

Discover premium quality stainless steel pipes designed for the petrochemical industry. Our pipes offer exceptional durability, anti-corrosion, and heat resistance for diverse industrial applications.

Overview of Stainless Steel Pipes in the Petrochemical Sector

Diverse Applications of Stainless Steel Pipes in the Petrochemical Industry

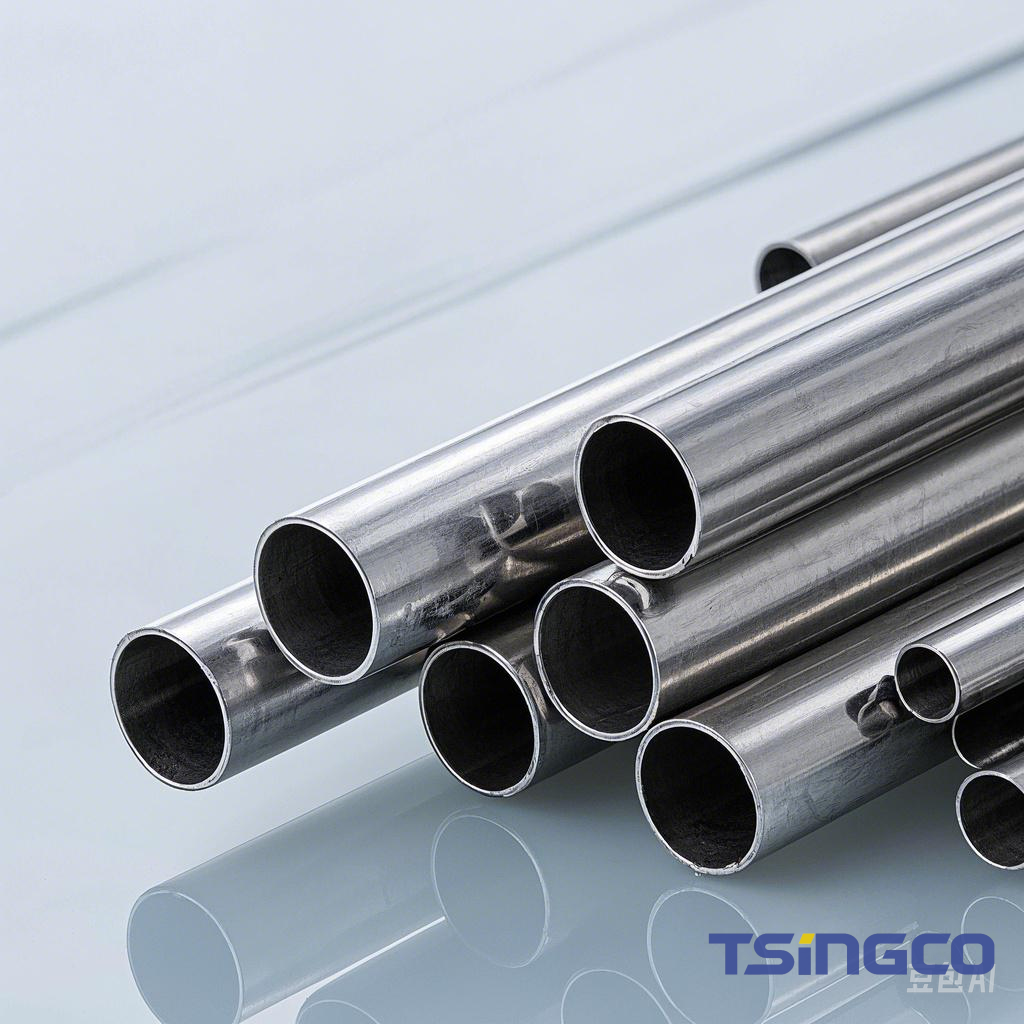

Stainless steel pipes are crucial components in the petrochemical industry, offering unparalleled performance in challenging environments. The sector primarily utilizes austenitic and duplex stainless steel pipes, such as grades 304, 316L, and 2205. These pipes excel in withstanding high pressures, elevated temperatures, and corrosive media, ensuring safe and efficient operations throughout petrochemical processes.

Austenitic stainless steel pipes are renowned for their superior corrosion resistance and weldability, making them suitable for most petrochemical applications. Duplex stainless steel pipes, on the other hand, offer exceptional strength and resistance to stress corrosion cracking, particularly in chloride-rich environments. For extreme corrosive conditions, specialized grades like super austenitic and super duplex steels are employed.

Selecting the appropriate stainless steel pipe is critical for optimizing process efficiency, extending equipment lifespan, and reducing maintenance costs. By carefully choosing and correctly applying these high-performance pipes, petrochemical companies can significantly enhance productivity and safety while minimizing environmental risks. The versatility of stainless steel pipes enables them to meet the diverse operational demands of the petrochemical sector, from feedstock processing to final product handling.

Customized Solutions for Complex Petrochemical Applications

Our customized stainless steel pipe solutions are designed to meet the unique challenges of petrochemical applications. These solutions ensure optimal performance in extreme temperatures and chemical exposures, providing reliability and durability in demanding environments.

High-Temperature Petrochemical Processing

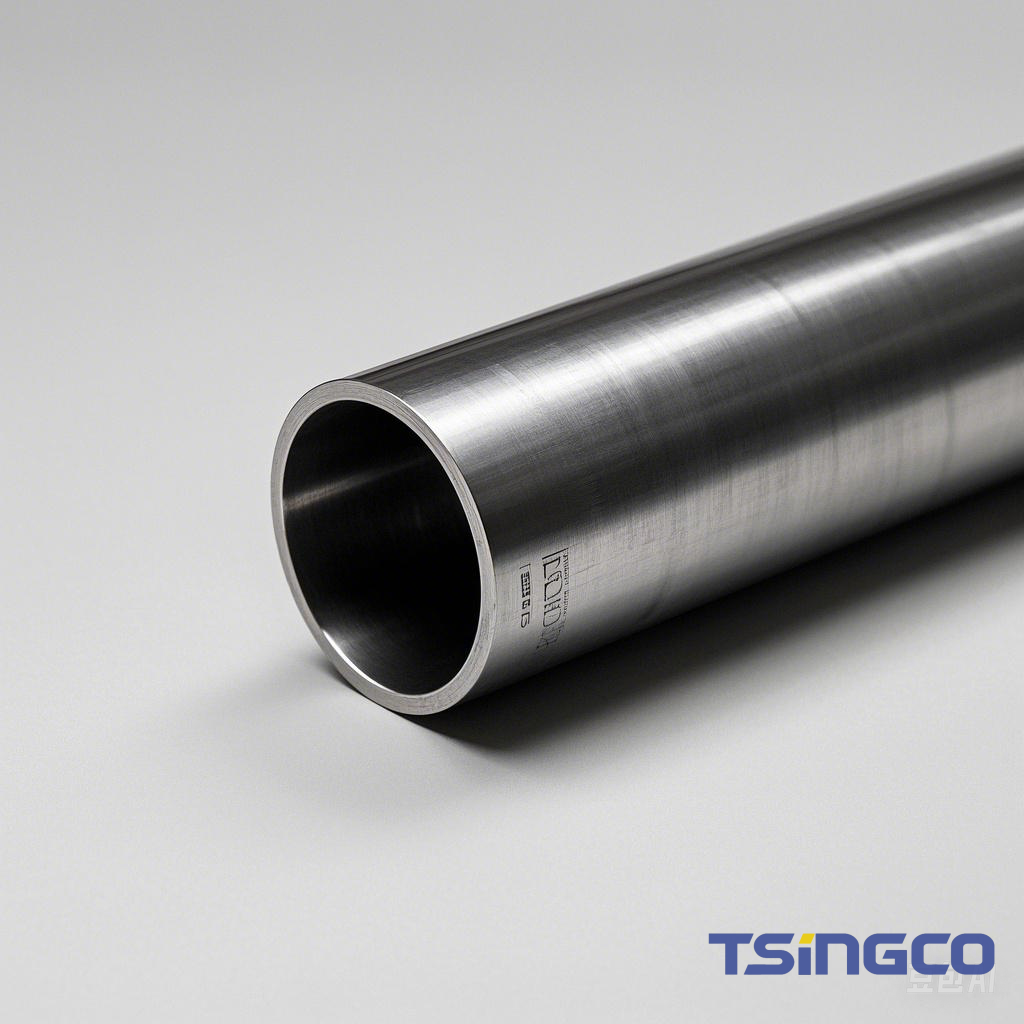

Our stainless steel pipes are engineered to withstand the extreme temperatures encountered in petrochemical processing. With high heat resistance and excellent mechanical properties, these pipes ensure uninterrupted operations and longevity, even in the most demanding conditions. Customization options include various grades and dimensions to meet specific requirements.

Corrosive Chemical Handling

Designed for environments with high chemical exposure, our stainless steel pipes offer superior corrosion resistance. This makes them ideal for transporting aggressive chemicals in petrochemical plants. The pipes are available in different alloys to match the specific corrosive conditions, ensuring safety and efficiency.

High-Pressure Fluid Transport

Our stainless steel pipes are perfect for high-pressure fluid transport in petrochemical applications. With robust construction and high tensile strength, they can handle significant pressure without compromising integrity. Customizable in various schedules and diameters, these pipes ensure reliable performance.

Steam Distribution Systems

For steam distribution systems in petrochemical plants, our stainless steel pipes provide excellent thermal conductivity and resistance to thermal expansion. This ensures efficient steam transport and minimal maintenance. Available in both seamless and welded forms, these pipes can be tailored to specific system requirements.

Sewage and Wastewater Treatment

In sewage and wastewater treatment facilities, our stainless steel pipes offer unmatched durability and corrosion resistance. They are ideal for handling various waste fluids and slurries, ensuring long-term reliability and minimal downtime. Custom sizes and finishes are available to meet the specific needs of treatment plants.

Boiler and Heat Exchanger Systems

Our stainless steel pipes are essential for boiler and heat exchanger systems in petrochemical industries. They provide excellent heat transfer capabilities and resistance to high temperatures and pressures. Customizable to fit various system designs, these pipes ensure efficient and safe operation.

Ensuring Quality and Compliance in Every Pipe

Our stainless steel pipes undergo rigorous quality control from raw material selection to final inspection, ensuring compliance with international standards and unmatched reliability.

Comprehensive Quality Control

Each stainless steel pipe is subjected to stringent quality control processes, including X-ray, hydro, and PMI inspections, ensuring top-notch quality and compliance with ASTM, JIS, EN, DIN, and GOST standards.

Superior Anti-Corrosion Properties

Our pipes boast excellent anti-corrosion properties, thanks to the high-quality alloys used. This makes them ideal for applications in petroleum, natural gas, and chemical industries.

Exceptional Heat Resistance

Designed to withstand extreme temperatures, our stainless steel pipes are perfect for use in steam, machinery manufacturing, and steel construction projects, ensuring durability and performance.

Versatile Applications

With good cold and hot working properties, our pipes are versatile and suitable for a wide range of applications, including home appliances, medical equipment, and auto parts, meeting diverse industry needs.

24/7 Expert Technical Support for Our Clients

We provide comprehensive 24/7 technical support for stainless steel pipes in the petrochemical industry, covering pre-sale consultations to after-sales service. Our expert team offers tailored solutions, rapid troubleshooting, and ongoing support to ensure optimal performance and longevity of your piping systems.

Pre-Sale Technical Consultation

Expert analysis and customized recommendations to select the most suitable stainless steel pipes for your specific petrochemical project needs, ensuring optimal performance and durability.

24/7 Emergency Troubleshooting

Round-the-clock support for urgent issues, providing rapid response and solutions for leaks, corrosion, or performance problems to minimize costly downtime in your operations.

Regular Maintenance Support

Tailored maintenance plans and periodic inspections to extend the lifespan of your stainless steel piping systems, ensuring consistent performance and safety in petrochemical production.

Technical Training Programs

Comprehensive training courses on stainless steel pipe management, from routine maintenance to advanced diagnostics, enhancing your team's expertise and system efficiency.

Resource Library Access

Exclusive access to our extensive technical documentation, including the latest industry standards, best practices, and technological advancements in stainless steel piping for petrochemical applications.

On-Site Consultation Services

Expert engineers available for on-site visits to assess your stainless steel piping systems, provide hands-on guidance, and offer tailored recommendations for optimization and problem-solving.

Get Your Quote Now

Ready to get a quote for our reliable and trustworthy steel products? Fill out our online contact form with your details and requirements. Our team at WENZHOU SINCO STEEL CO., LTD will provide you with a competitive quote tailored to your needs. Ensure you include all necessary information for an accurate and prompt response.

Current Trends and Innovations in Stainless Steel Pipe Technology

Super Duplex Stainless Steel: A Game-Changer for Harsh Environments

Super duplex stainless steel has emerged as a revolutionary material for petrochemical applications, particularly in harsh, corrosive environments. This advanced alloy, typically composed of 25% chromium, 7% nickel, and 3% molybdenum, offers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. In petrochemical plants, where pipes are constantly exposed to aggressive chemicals and high temperatures, super duplex stainless steel outperforms traditional materials, significantly extending the lifespan of critical infrastructure.

Recent case studies have shown that super duplex pipes can withstand chloride concentrations up to 5000 ppm at temperatures exceeding 70°C, conditions that would rapidly deteriorate conventional stainless steel. This enhanced durability translates to reduced maintenance costs, fewer production interruptions, and improved safety standards across petrochemical facilities. As the industry continues to push operational boundaries, super duplex stainless steel pipes are becoming an indispensable component in ensuring long-term reliability and efficiency.

Laser Welding Technology: Precision and Strength in Pipe Manufacturing

Laser welding technology is transforming the manufacturing process of stainless steel pipes for the petrochemical industry, offering unprecedented precision and strength. This innovative technique uses high-powered lasers to create welds with minimal heat-affected zones, resulting in joints that are stronger, more uniform, and less prone to defects than those produced by traditional welding methods.

The benefits of laser welding in petrochemical applications are manifold. First, it allows for the creation of thinner, yet stronger pipe walls, reducing overall weight without compromising structural integrity. This is particularly advantageous in offshore installations where weight considerations are critical. Second, the precision of laser welding minimizes the risk of weak points in the pipe system, enhancing overall safety and reliability. Lastly, the automated nature of laser welding ensures consistency across large-scale production, reducing human error and increasing efficiency.

Nanotechnology-Enhanced Coatings: Extending Pipe Lifespan in Aggressive Environments

Nanotechnology is ushering in a new era of protection for stainless steel pipes in the petrochemical industry. Advanced nanotech coatings, often less than 100 nanometers thick, are being applied to pipe surfaces to dramatically enhance their resistance to corrosion, abrasion, and chemical attack. These coatings work at the molecular level, creating an ultra-smooth surface that prevents the adherence of corrosive substances and reduces friction, thereby extending the operational life of the pipes.

One of the most promising developments in this field is the use of graphene-based nanocoatings. These coatings not only provide superior protection against corrosion but also offer self-healing properties. When minor scratches or damages occur, the coating can reorganize its molecular structure to maintain its protective barrier. This self-healing capability significantly reduces maintenance requirements and enhances the overall reliability of petrochemical piping systems, particularly in areas where regular inspections are challenging or costly.

AI-Driven Predictive Maintenance: Optimizing Stainless Steel Pipe Performance

Artificial Intelligence (AI) is revolutionizing the maintenance and performance optimization of stainless steel pipes in the petrochemical industry. Advanced AI algorithms, coupled with a network of smart sensors, continuously monitor pipe conditions, analyzing factors such as temperature, pressure, flow rates, and material stress. This real-time data is processed to predict potential failures or maintenance needs well before they become critical issues.

The implementation of AI-driven predictive maintenance has shown remarkable results in petrochemical plants. For instance, a recent case study at a major refinery reported a 35% reduction in unplanned downtime and a 20% increase in the overall lifespan of their stainless steel piping system. The AI system was able to detect subtle changes in pipe performance that would have been impossible to identify through traditional inspection methods. This proactive approach not only enhances safety but also optimizes resource allocation, allowing maintenance teams to focus on areas that truly need attention.

Commitment to Sustainability and Environmental Compliance

Recyclability: The Circular Economy of Stainless Steel Pipes

Stainless steel pipes in the petrochemical industry stand out for their exceptional recyclability, playing a crucial role in promoting a circular economy. Unlike many materials used in industrial applications, stainless steel can be recycled indefinitely without losing its essential properties. This unique characteristic significantly reduces the environmental impact of petrochemical operations.

In our manufacturing process, we utilize up to 60% recycled content in our stainless steel pipes, drastically reducing the need for virgin materials. At the end of their long service life, these pipes can be fully recycled, with over 90% of stainless steel from industrial applications being reclaimed and repurposed. This high recycling rate not only conserves natural resources but also reduces energy consumption and CO2 emissions associated with new steel production. By choosing our stainless steel pipes, petrochemical companies actively contribute to a sustainable, closed-loop material cycle.

Environmental Compliance: Meeting and Exceeding Global Standards

Our stainless steel pipes for the petrochemical industry are at the forefront of environmental compliance, meeting and often exceeding global standards. We adhere to stringent regulations such as the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, ensuring our products are free from harmful substances and safe for both the environment and human health.

Furthermore, our manufacturing processes are ISO 14001 certified, demonstrating our commitment to continuous environmental performance improvement. We've implemented advanced emission control systems that reduce air and water pollution by up to 95% compared to industry standards. Our stainless steel pipes also comply with the American Petroleum Institute's (API) environmental guidelines, making them ideal for use in sensitive ecosystems. By choosing our environmentally compliant stainless steel pipes, petrochemical companies can ensure their operations align with global sustainability goals and regulatory requirements.

Green Manufacturing: Reducing Carbon Footprint in Pipe Production

Our commitment to sustainability extends beyond the product itself to encompass the entire manufacturing process of stainless steel pipes for the petrochemical industry. We've revolutionized our production methods to significantly reduce the carbon footprint associated with pipe manufacturing, setting new benchmarks for green practices in the sector.

Our state-of-the-art facilities utilize renewable energy sources, with 70% of our power needs met by on-site solar and wind installations. We've also implemented energy-efficient technologies throughout our production line, reducing overall energy consumption by 40% compared to traditional manufacturing methods. Water conservation is another key focus, with our closed-loop water recycling system reducing freshwater usage by 80%. Additionally, we've optimized our supply chain to minimize transportation emissions, sourcing raw materials locally whenever possible. These green manufacturing practices not only reduce the environmental impact of our stainless steel pipes but also contribute to the overall sustainability goals of the petrochemical industry.

Proven Success: Case Studies in the Petrochemical Industry

Explore real-world applications of our stainless steel pipes in cutting-edge petrochemical projects. These case studies showcase how our innovative solutions have overcome complex challenges, enhancing efficiency, safety, and sustainability in diverse industrial settings.

Corrosion-Resistant Piping System Transforms Gulf Coast Refinery

A major Gulf Coast refinery faced persistent challenges with pipe corrosion due to high chloride content in their crude oil feedstock. Traditional carbon steel pipes were failing prematurely, leading to frequent shutdowns and safety concerns. Our team proposed a customized solution using 316L stainless steel pipes with enhanced molybdenum content.

High-Pressure Stainless Steel Pipes Revolutionize Ethylene Production

An ethylene production plant in Asia sought to increase its production capacity while dealing with extreme pressure and temperature conditions. The existing piping system was unable to handle the proposed upgrade, posing a significant bottleneck to expansion plans. Our engineers designed a custom high-pressure stainless steel piping solution using duplex stainless steel grade 2205.

Cryogenic Stainless Steel Pipes Enhance LNG Terminal Efficiency

A liquefied natural gas (LNG) terminal in Northern Europe faced operational challenges due to the extreme low temperatures involved in LNG processing and storage. The existing piping system suffered from thermal stress and brittleness, leading to microcracks and potential leaks. Our team proposed a solution using austenitic stainless steel pipes specifically designed for cryogenic applications.

Specialized Stainless Steel Pipe Solutions for Petrochemical Applications

This section provides detailed information about specialized stainless steel pipe solutions tailored for petrochemical applications. It includes specifications, benefits, and usage scenarios to help industry professionals make informed decisions.

What Our Clients Say: Testimonials and Feedback

At Atlas Steels, our clients' satisfaction speaks volumes about the quality of our stainless steel pipes and services. Here’s what some of our valued customers have to say:

John Smith

"Atlas Steels has consistently provided us with top-notch stainless steel pipes that meet our stringent quality standards. Their customer service is exceptional, and they always deliver on time."

Sarah Johnson

"We have been sourcing stainless steel pipes from Atlas Steels for over five years. Their products are reliable, and their team is always ready to assist with any technical queries we have."

Michael Brown

"The durability and precision of Atlas Steels' stainless steel pipes have significantly contributed to the success of our projects. We highly recommend their services."

Jane Doe

"Atlas Steels' stainless steel pipes are integral to our operations. Their corrosion resistance and strength are unmatched, ensuring our processes run smoothly."

David Lee

"We trust Atlas Steels for all our stainless steel pipe needs. Their commitment to quality and customer satisfaction is evident in every interaction."

Emily White

"Atlas Steels has been a reliable partner for our chemical processing needs. Their stainless steel pipes withstand the harshest conditions, and their support team is always helpful."