Durable Stainless Steel Pipe Solutions for Energy Transportation

Find the best stainless steel pipes that can be used for energy transport and are unrivaled in terms of durability and resistance to corrosion. Highly suitable for many industrial uses.

Stainless Steel Pipes for Energy Transportation Applications

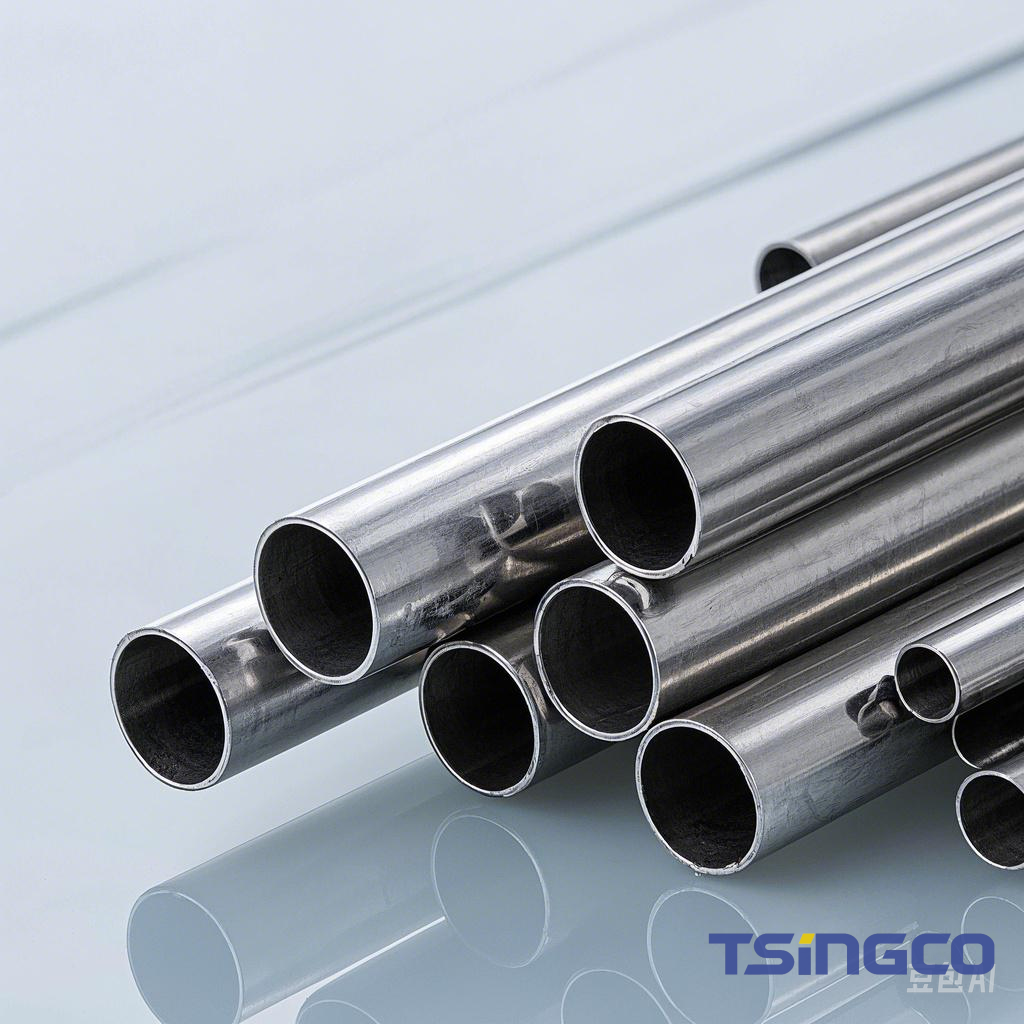

The development of our high-tech stainless steel tubes is purposefully intended to meet the stringent demands of energy conveyance. The types of these high-performance pipes which exhibit outstanding corrosion resistance include seamless and welded varieties, possessing an unmatched strength that ensures reliability in any energy sector application.

The product line consists of seamless pipes. The diameters range from 6-914mm and the wall thickness from 0.5-70mm: this makes them an excellent option for oil and gas transportation (including other energy resources) due to their high quality. Moreover, we provide welded pipes with a diameter varying between 10-2500mm which are used in large energy transport systems. All our pipes comply with strict industry standards such as ASTM, ASME, and EN; this means that they can always be trusted when reliability is essential for critical systems within your energy infrastructure.

The stainless steel pipes demonstrate superiority in high-pressure and high-temperature conditions, having good mechanical properties and heat resistance. Our pipes are suitable for use in offshore platforms, refineries or cross country pipelines where they can provide the required performance as well as durability in energy transportation: these aid in the effective delivery of important energy materials with safety being a priority.

The Core Values Of Our Stainless Steel Pipes

Introducing our stainless steel pipes and its unprecedented benefits, crafted to exhibit exceptional resistance against corrosion and strength in durability. High performance even under extreme environmental conditions is what it offers.

Superior Corrosion Resistance

The steel pipes we offer are developed with advanced alloys to provide optimal corrosion resistance, which sets them apart as ideal for hostile industrial settings and guaranteeing durability throughout their lifespan.

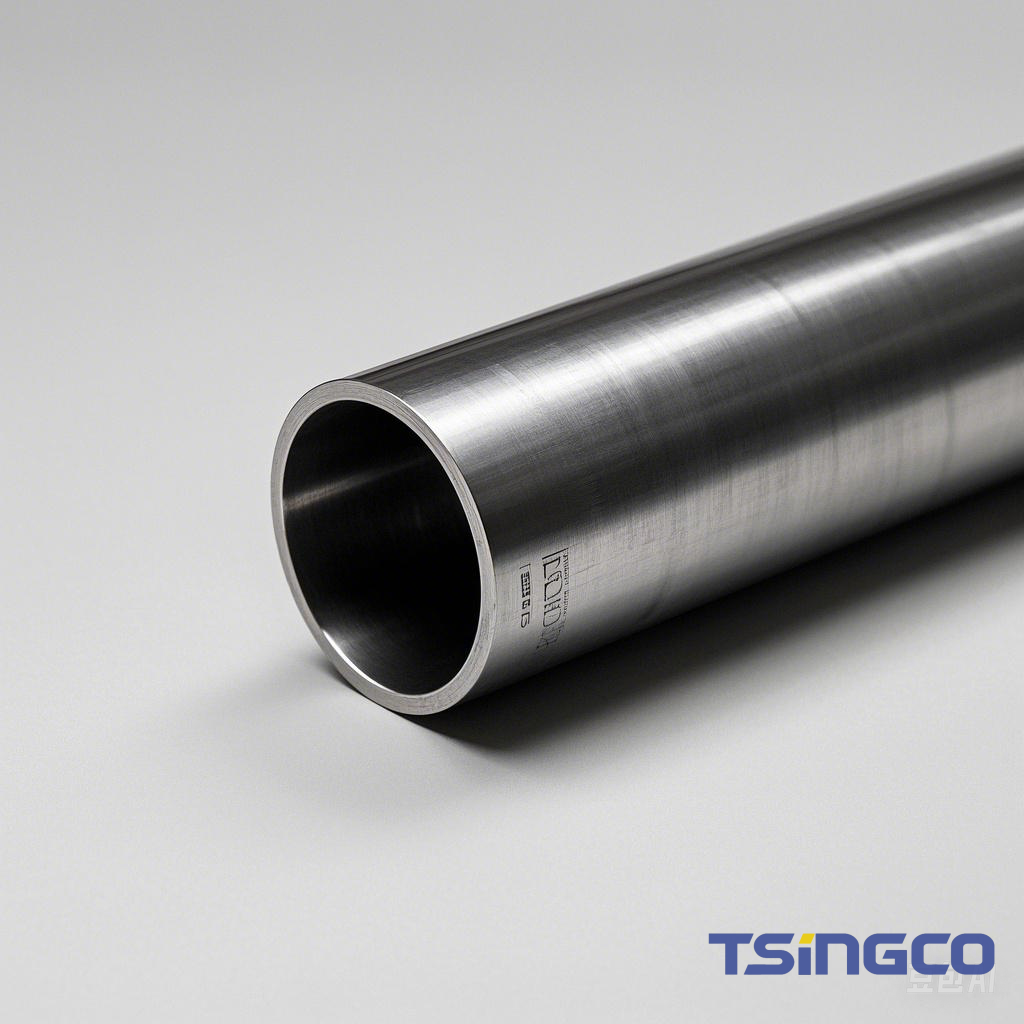

Exceptional Durability

Designed for extreme durability, our stainless steel pipes are engineered to resist the harshest conditions and maintain their structural integrity, ensuring reliability even in the most demanding of environments.

Versatility in Extreme Environments

The stainless steel pipes are designed for versatility; they can be used in extreme temperatures and high pressure which makes them suitable for a lot of industrial applications.

Customizable Specifications

A wide range of sizes and grades are available for our stainless steel pipes, custom-designed to meet your special specifications and standards, thus allowing you to get an ideal solution for your assignment.

Technical Specifications For Energy Transportation

We manufacture stainless steel pipes that are top-notch, made with utmost care to meet high standards of quality and precision. The products come with detailed technical specifications that cover dimensions, wall thickness and material grades which make sure the user gets the best out of reliability and long term use for different industrial applications.

Specification | Value |

|---|---|

Material Grades | 304, 304L, 316, 316L, 2205 |

Outer Diameter (OD) | 6 mm to 1219 mm |

Wall Thickness (WT) | 0.5 mm to 12.7 mm |

Length | Up to 12 meters |

Standards | ASTM A312, ASTM A269, ASTM A213 |

Surface Finish | Polished, Bright Annealed, Descaled |

Manufacturing Process | Seamless, Welded |

Tolerance | ±0.1 mm to ±0.5 mm (OD), ±10% to ±15% (WT) |

Delivery State | Hot Finished, Cold Finished, Bright Annealed |

Testing | Eddy Current Testing, Hydrostatic Testing |

Applications | Chemical Processing, Oil & Gas, Food & Beverage, Pharmaceuticals |

This table provides a comprehensive overview of the technical specifications of our stainless steel pipes, ensuring you have all the necessary information to make an informed decision.

Case Studies

Dive into our successful case studies that reveal outstanding performance and advantages of stainless steel pipes in energy transport projects. In each case study, the distinctive challenges are underscored along with our out-of-the-box problem solving which depicts the trustworthiness and effectiveness of what we offer.

High-Performance Stainless Steel Pipes in Offshore Oil Rigs

The utilization of our stainless steel pipes was key to the triumph of an offshore oil platform undertaking, where robustness and resilience to brutal marine settings played a crucial role. The pipes showed outstanding corrosion resistance which means that they can be depended on over the long term reliability; this minimizes maintenance costs. This real-life example underscores the capability of our products to hold up under extreme conditions— an impervious option is developed for energy transport ventures into challenging environmental settings.

Enhancing Efficiency in Natural Gas Pipelines

Our stainless steel pipes were crucial elements that resulted in an improved efficiency and security level with respect to a major project related to natural gas pipeline. The ability of the pipes to offer a high tensile strength plus resistance to high pressure conditions made it possible for natural gas transportation to be easy and safe without any hitches. This case study presents the positive results from using our products— evidential in performance advantages, therefore playing a part in successful safety measures for energy transport undertakings as well.

Reliable Solutions for Chemical Plant Energy Transport

Chemical corrosion and high temperatures are no match for the stainless steel pipes that compose a part of this chemical plant's energy transport system; they have been carefully chosen. The project called for materials capable of combating aggressive chemicals as well as extreme heat, and in this regard our pipes did not disappoint. This particular instance acts as an example demonstrating the trustworthiness and longevity of our products within these specific high-stress industrial uses.

Energy Transport Solutions with Stainless Steel Pipes

Get to know the various situations where our stainless steel pipes find use in the energy sector. From oil and gas down to water supply and steam transportations, our pipes ensure reliability plus efficiency under various demanding conditions.

Oil and Gas Transportation

Incorporating stainless steel in pipelines is important for the protection and effective transportation of oil plus gas. They are highly resistant to corrosion which ensures they serve the purpose even in harsh environments along with high pressure systems without flow interruptions and low maintenance cost.

Water Supply Systems

The sturdy steel tubes are what we can consider the lifeline of present day water schemes. Due to their anti-corrosive nature, stainless steel pipes have low biofouling which means that the water reaching you is clean and safe. Our pipes suit the needs of both urban and rural areas: they demonstrate long-term dependability and easy installation and maintenance, which make it a lot easier for the towns and cities' local water supply systems to choose us as their preferred choice.

Steam Transportation

When it comes to steam transportation, our stainless steel pipes outshine others because of their high resistance to heat and strength levels. They find ideal use in industrial settings wherein steam plays a role in heating systems, generating power and processing. Our piping guarantees effective flow of steam without wastage of energy— thus playing a role in the safety and effectiveness of the entire system.

Sewage Treatment Plants

Stainless steel pipes are very important in sewage treatment plants where the corrosive substances take place and a product's durability is needed. Our pipes guarantee safe transportation of wastewater which leads to the support of the treatment process; this also contributes to efforts to sustain environmental standards. The structural composition and design of our pipes make them capable of meeting the challenging needs typical in sewage treatment works.

Get a Quote

Are you prepared to make the next move? Get in touch with us now to find out more details or ask for an estimate on our high-quality stainless steel pipes. We assure you that our staff will come up with the most suitable options that fit your requirements.

Quality Stainless Steel Pipes Products for Energy Transportation

Unveil our high-quality stainless steel pipe products tailored for energy transport applications. We ensure superior durability and corrosion resistance that guarantee safe and efficient delivery of oil plus gas. Discover it today!

Customer Testimonials About Stainless Steel Pipe for Energy Transportation

John Smith

SINCO STEEL's stainless steel pipes have been a game-changer for our energy transportation needs. The product's reliability and the company's attention to detail are unmatched. We couldn't be happier with our choice.

Maria Gonzalez

The quality of SINCO STEEL's pipes is exceptional. Their professional equipment and excellent team ensured that every detail was perfect. Our energy transportation system has never been more efficient.

Li Wei

We have been using SINCO STEEL's stainless steel pipes for over a year now, and the reliability is outstanding. Their commitment to quality and customer satisfaction is evident in every product.

Ahmed Khan

SINCO STEEL's dedication to product reliability and customer service is impressive. Their stainless steel pipes have significantly improved our energy transportation processes. Highly recommended!

Emily Johnson

The positive experiences we've had with SINCO STEEL's products are numerous. Their stainless steel pipes are incredibly reliable, and the team's professionalism is top-notch.

Hiroshi Tanaka

SINCO STEEL's stainless steel pipes have exceeded our expectations in terms of reliability and performance. Their thorough inspection process ensures we receive only the best products.

Frequently Asked Questions About Stainless Steel Pipe for Energy Transportation

The section of our Frequently Asked Questions (FAQ) module gives more information about the stainless steel pipes. This includes details such as specifications, applications, and maintenance.

Our stainless steel pipes come in various specifications, including different sizes, thicknesses, and lengths. We adhere to standards like GB/T 14975-2002, GB/T 14976-2012, and ASTM A312. For detailed specifications, please refer to our comparison chart of different standard tolerances.

Our stainless steel pipes are used in various industries, including petroleum, chemical, food, and shipbuilding. They are ideal for applications requiring high corrosion resistance, durability, and strength. Specific applications include water supply systems, gas transportation, and industrial pipelines.

Regular maintenance of stainless steel pipes includes cleaning with mild detergents and water to remove dirt and debris. Avoid using abrasive materials that can scratch the surface. For polished pipes, periodic re-polishing may be necessary to maintain their appearance.

Yes, we can cut stainless steel pipes to your desired length. Our standard lengths are 5.8m or 6m, but we can provide lengths up to 12 or 13 meters. Custom cutting methods like laser, plasma, and water-jet cutting are available upon request.

We offer various finishes for our stainless steel pipes, including pickled, polished, and bright annealed. Polished finishes can be done to #240 and #320 grit levels. The finish type depends on the specific application and customer requirements.

Yes, we provide a range of stainless steel pipe fittings, including elbows, flanges, and reducers. These fittings are available in various sizes and specifications to match our stainless steel pipes, ensuring a complete piping solution.

The standard delivery time for stainless steel welded tubes is approximately two weeks for orders less than two containers. However, delivery times may vary based on factors like special grades, sizes, and order quantities.

Our standard packaging includes thick woven plastic bags. We also offer wooden cases or customized packaging based on your requirements. Each pipe is carefully packaged to ensure safe transportation and delivery.

We follow the ASTM A511 standard for thick-walled stainless steel pipes. These pipes are used in mechanical applications and for producing hollow components like nozzles and couplings, where corrosion resistance and high-temperature strength are essential.

The most popular grades of capillary tubes are BA grade and EP grade 316L. These tubes are widely used in various applications and adhere to the ASTM A269 standard, ensuring high quality and performance.